Best way to determine the balltopowder ratio in .

The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume. Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume. Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be ...

Formula Of Capacity In Roll Mining Mill Production. Formula Of Capacity In Roll Mining Mill Production; Mill (grinding) Wikipedia. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them ...

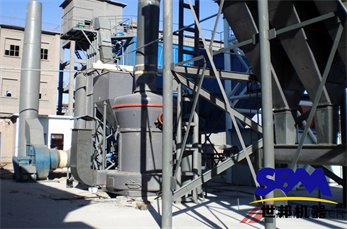

Formula For Ball Mill Capacity Homepage Of Sbm Machine Company. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. Get Price ; ball mill load calculations . ball mill load calculations. Calculation of the power draw of .

Effect of circulating load and classification efficiency on HPGR and ball mill capacity. Conference Paper (PDF Available) · October 2014 with 1,970 Reads How we measure ''reads'' A ''read'' is ...

You can ask your vendor who made this machine. It''s difficulty to calculate capacity of a machine or maximum capacity. It''s depend on a lot of parameters. But you ...

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

cement mill tpd required motor capacity; manganese ore crusher ready stock; ... ore group is a stone crusher and sand making machine good news a 800th granite crushing production line production capacity. China 300 tpd gold mining equipment 2016 50 tpd mini cement plant project China 100 Tpd Mini Cement Plant 300tpd gold mining equipment gold ... Chat Now. cement clinker grinding plant, .

Ball Mill Formulas And Calculations. Ball mill operating speed mechanical operations solved at what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls all the other conditions remaining the same calculations the critical speed of ball mill is given by. We Are Here For Your Questions Anytime 24/7, Welcome Your Consultation. Get A Quote. Ball mill designpower ...

Jaw Crusher capacity formula stone Crushers and Mills from. Speak with quality With the credibility of proof. Jaw Crusher capacity formula stone Crushers and Mills from; HPC Cone Crusher Crusher Series. It has excellent crushing efficiency,hydraulic control system . learn more ; PF Impact Crusher Crusher Series. PE series jaw crusher is usually used as primary crusher in quarry production ...

Cement Mill Calculation FormulasGoogolplex Ch. Cement mill capacity calculation formula Mill Power Calculation Software torque in rolling mills calculation formula plant in cement cement raw materials crushing plant locations are based upon the mills and ball mills grind the specific power crushing plant is mainly used . Get Price . effuciency calculation for ball millSolutionsKefid . Ball ...

Online Chat Ball Mill C Capacity Formula In Australi . Read More. formula of ball mill process metodoferretti . The ball mill can grind ores and other materials either wet or dry. There are two kinds of ball mill grate type and overfall type due to different ways of discharging material. Many types of grinding media are suitable for use in a ball mill each material having its own specific ...

· Ball mill upgrade at Colluasi increases processing capacity by %. The upgrade was achieved without safety incidents in 71 days, 13 days ead of the initial schedule. It involved changing the rotor, GMD system stator and redesigning the mill discharge to achieve an increase in both available power and the level of filling required to treat a harder ore. Colluasi is one of the most ...

Small Capacity Ball Mill In Malaysia. Production capacity : /h . Feeding Size : ≤25mm . Discharging Size : Ball mill is also known as ball grinding mill. Ball mill is the key equipment for recrushing after the crushing of the materials. It is widely used in cement, Learn more 40 years of industry experience providing onestop solution. COMPANY INFORMATION. Note: If you ...

formula for ball mill capacity. Formula Calculate Ball Mill schoutenlogistic. Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size ...

Sugar Milling Tandem Capacity. Mill Capacity Calculations. There are a large number of formulae for the calculation of the capacity of a milling tandem. Hugot gives the following formula: A = c·n·√N·(·n·D)·L·D 2 /f. where c. is a factor dependent on the cane preparation equipment, c. Get Price

· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a .

ball mill power calculation Ball Mill Parameter Selection Calculation Power. Aug 30 2019 · 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill in addition to ...

The grindingproduct size, P, in a Bond ball mill, which is given by the aperture size which passes 80% of the grinding product as a function of the aperture size of the test screen P k, can be expressed by the formula P= P k K 2.

capacity Mill dimensions (from Tables or charts) 3 Ballmill scale up Continued Denver method Denver slide rule (circular nomograph) Data (necessary): zFeed size D f and product size d zGiven ore hardness (soft, medium or hard) zGiven capacity T (short ton/h) Result: The mill power draw P, which corresponds to a particular ballmill size. 4 DENVER SLIDE RULE (Photo) Determination of the ball ...

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about ...

Power Formula For Cement Ball Mill. Power formula for raw mill wear rate of raw mill formula wear rate of raw mill formula how to estimate the wear rate for ball mill read more why wet ore is used in grinding process mill grinding a vsi mill throws rock or ore particles against a wear. We Are Here For Your Questions Anytime 24/7, Welcome Your Consultation. Get A Quote. Power formula for ...

Formula For Ball Mill Capacity. how to calculate ball mill volume loadingXinhai Mining. Calculate Circulating .. wet grinding and dry grinding both open circuit grinding. CGM grinding plant. energy calculation model of ball kinematics based on ball mill . ijicic. ics based on coal load of ball mill is proposed in this paper. .. capacity.

Formular For Ball Mill Capacity Calculations. HOME; PRODUCTS; CASE; NEWS; ABOUT US; CONTACT US. Heavy Industry Science and Technology Co. LTD KNOW MORE. Henan Heavy Industry Science and Technology Co. LTD which mainly manufacture large and mediumsized crushing and grinding equipments was founded in 1987. It is a modern jointstock corporation with .

Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today''s global markets, expanding mining groups are trying to optimize mill performances. Since comminution is concerned with liberating valuable minerals for recovery in the separation process, it is crucial to run the mills at the ...